Prototyping is making miniature pieces that exhibit essential components’ visual and functional properties. The primary purpose of creating prototypes is to examine and verify the correct functioning of various modules in the final design. Prototype construction is used in multiple industries before the final production begins.

On the industrial scale, the prototypes are intricate. Hence, CNC machines are best for this job. There are many kinds of prototypes. However, CNC machines are commonly used for manufacturing functional prototypes. Although the process is 80 to 90% automated, some precautions are necessary. Let’s look at them so you can get the maximum out of the production.

Measures That Ensure an Accurate Prototype

There are numerous methods to build prototypes, and most companies have their standards. However, the below-mentioned precautions remain the same for all prototyping methods.

Choosing The Right Prototyping Technique

Choosing the correct prototyping technique is critical to ensure the desired outcome. Since CNC machines are the most reliable, efficient, and detail sensitive, they make the aptest choice for creating prototypes.

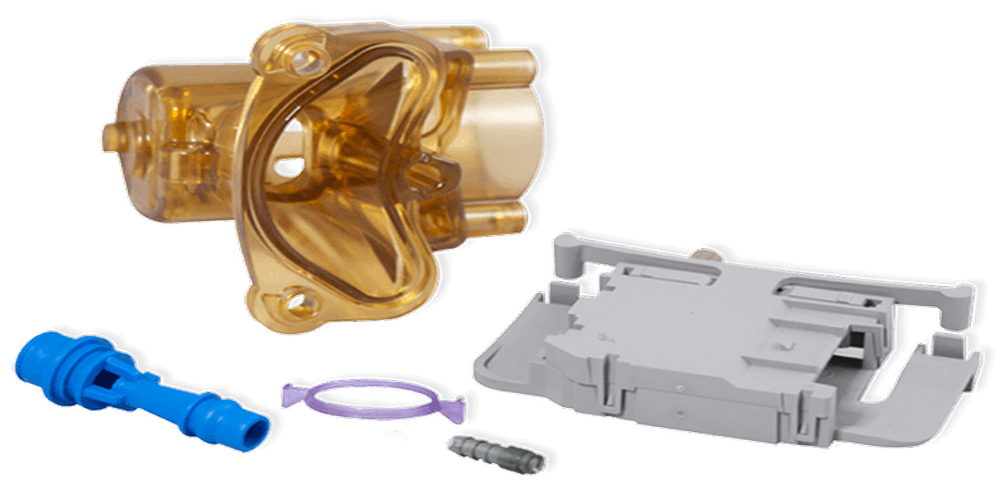

However, other techniques like 3D printing, vacuum casting, and injection molding are also preferred for building prototypes.

Small Quantity

Since prototyping is only done to ensure the proper functioning of the components, it is critical to make smaller batches. Most CNC prototyping machining service companies are not commercial-level industries and only accept smaller orders (100 pieces or so). Building an optimal number of prototypes helps you analyze the users’ inclination at lesser costs.

Creating A Design

Beginning the prototyping process without initial designs results in faulty component construction. Therefore, engineers and experts create a fundamental blueprint before prototyping.

In the case of CNC machines, CAD files are prepared and reviewed. After that, the programs are incorporated with additional instructions for giving the machine the required specifications.

Testing Is Vital

Testing is the most critical stage of prototyping. A series of tests are conducted on the prototype to ensure its working. If the results differ from the desired output, the necessary amendments are made, and another prototype is constructed.

Where Are CNC-Manufactured Prototypes Used?

When opting for CNC machines for prototypes, it is essential to note which industries have their applications. Prototypes are used in various industries, from health to automobile to aerospace.

Medical

The healthcare industry is progressing rapidly, and so is the need for error-free production. Since complex equipment and implants are being synthesized in laboratories, it is essential to construct a prototype to ensure the correct working. Some familiar illustrations which use prototypes are MRI machines, implants, orthotic devices, and research and safety equipment.

Military

The second most prominent industry which utilizes CNC prototype machining is the military. After their prototypes have been finalized, different types of ammo and war vehicles are set into production. Communication devices, tracking equipment, security systems, and ammunition are also prototyped with CNC machines.

Automobile

The automobile industry comes up with innovations every day. However, before inputting the designs into the manufacturing line, experts construct prototypes to ensure their correct working. Once the prototype is tested and verified, the final production initiates.

The Bottom Line

Making a prototype is essential for several reasons. Firstly, it exhibits all the functional operations of the component, and flaws are fixed before the product reaches the consumer market. Since prototypes require the utmost precision, CNC machines make the ideal choice for their construction.

Although there are many ways to build prototypes, some precautions remain unchanged. The excerpt discusses all the essential precautionary aspects to help you make an accurate prototype.